Hofmann Megaplan Blog

Over the last few months, ADAS has been an unavoidable subject - and for many, it is a step into the unknown. Many shows this year already including the CV Show and Automechanika have demonstrated the need for specialised equipment and valuable industry knowledge.

Although many garage owners won't admit it, the demand for ADAS calibrations are beginning to scare even the most knowledgeable. These technologically advanced systems are fast becoming a necessity to keep your customers.

Whilst many specialists are worried about the lack of awareness, this has been the main focus for Hofmann Megaplan.

ADAS Calibration Training - Advanced Systems for Simple Solutions

Held at our state-of-the-art showroom and training centre, our ADAS equipment experts were on hand for a free educational day covering our totally digital solution to ADAS diagnostic systems.

Visitors had the opportunity to gain & share knowledge around multiple Advanced Driver Assistance Systems. Unravelling the mystery of ADAS has never been easier!

"The advanced ADAS system is able to complete more calibration checks in less time due to its digital set up and smart operational features. Minimal interaction is needed from the operator. This is a method of completing ADAS that is making people rethink how they invest in technology. The whole-lift cost of Advanced ADAS vs. standard ADAS is a no brainer. You'll be saving tens of thousands through FOC board updates alone and people are realising that here today."

The team hosted live demonstrations throughout the day, completing more calibration checks with the advanced system on the morning of the event than a standard system could in a day. The brand new Advanced ADAS Calibration system was a big hit with visitors, prompting a lot to rethink how they invest in ADAS calibration equipment.

Advanced ADAS Calibration - The Right Investment

It has been designed specifically for Hofmann Megaplan to provide ADAS calibrations in the most cost and labour efficient way imaginable. A 65" TV Monitor provides a totally digital solution to updates, instead of purchasing costly boards to deal with different vehicle requirements, whilst the operation is smart enough to take measurements and adjust the screen perspective to avoid time spent trying to line up a vehicle.

Other ancillary garage equipment was also on show, including the full range of Wheel Alignment machines and Automatic Tread Measurement Systems. These are services proven to boost revenue in garages and so were of great interest to visitors.

The TreadSmart is the latest offering in this space joining the handheld TreadReader, offering affordable tread scanning with integrated Number Plate Recognition for fast and transparent reporting.

To all of you who visited us at our showroom, we thank you for making it our best open day to date!

Has anyone ever mentioned investing in a vehicle wheel lift? Maybe you've noticed as the day goes on your fitter's speed to carry out jobs decreases?

Vehicle wheels are heavy and you're probably lifting them more than you realise. Are the signs not clear enough yet?

You may be about to lose a valuable member of your team to serious back problems if you don't heed these signs of physical strain. Worse still, you could be out of action!

By investing in a safe and affordable wheel lift, you can look after the well-being of yourself, your team and boost the productivity of your garage at the same time.

Back, shoulder and neck injuries are very common within the industry and these problems are no joke! Manual handling injuries account for nearly half of all tyre-bay related incidents. (HSA)Taking the strain out of wheel lifting!

You could benefit immensely from investing in a reliable and sturdy wheel lift.

Check out our 5 reasons why you need a wheel lifter in our previous blog!

Raise your fitters' capabilities with the right wheel lift..

As you would come to expect from Hofmann Megaplan, we deliver high quality wheel lifting machines to reduce the health implications and improve the efficiency of your tyre bay or garage.

Ensuring you have the right wheel lift is crucial in guaranteeing the device is used regularly as a daily driver in your garage. Ease of use, portability and speed of operation are just some of the factors you'll be considering.

Unlike tyre changers and wheel balancers, wheel lifts are often forgotten about or the cheapest model on the market is purchased, but does not lead to operational efficiency. You spend more time annoyed at your rubbish wheel lift!Take a look at our reliable range of competitively priced Premium Wheel Lifts today:

Contact us online now or call us today on 01480 8-9-10-11 to order your electric wheel lifter now or for more info.

Looking to enhance your garage revenue with wheel alignment? Maybe your customers are becoming wiser to alignment and searching for a more comprehensive service? Offering 4 wheel laser alignment could be the answer.

Every garage is looking for new ways to strengthen their services - especially within alignment. Having proved to be one of the most lucrative sources of revenue throughout the automotive equipment industry, wheel alignment is continuing to evolve.

4 Wheel Laser wheel alignments may be the next step in conquering your closest rivals. Step one: understanding it!

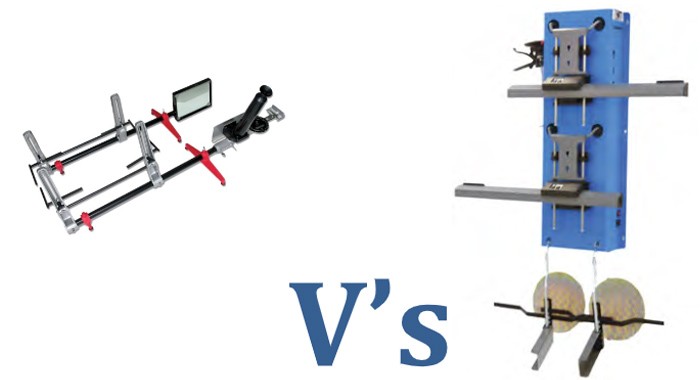

4 Wheel Laser vs Optical Gauges

From the uninitiated, we often get asked the difference in these terms and how they are related if not the same thing.

Put simply, 4 wheel laser alignment measures on all four wheels ensuring the car is no longer crabbing, a phrase to remember is the "rear wheels steer the vehicle". Also when you consider 70% of manufacturers now have rear tracking as well as the front, there is extra revenue to be made, but the most important aspect is you will have a straight steering wheel which means no more driving down the road making adjustments on the side of the road.The generic process of Optical gauges will check the track of the front and rear wheels only, but will not straighten the steering wheel or stop the car crabbing which is highly important on todays modern cars because of the highly complex electronics such as ADAS.

Naturally 4 wheel laser alignment is a more lucrative service to offer when compared to Optical gauges, and the results from 4 wheel laser alignment means better performance from your customer's vehicle.

4 Wheel Laser Wheel Alignment Explained

You shouldn't be overwhelmed by this technology as it is becoming common place in garages across the UK.

Car wheels are not just set up to just point forwards. To ensure the car drives smoothly and functions properly, the wheels are set up to point at specific angles. These angles can be tiny but failing to set them up can ruin the driver's experience.

Laser alignment makes this process simple, using light beams to project any misalignments onto the 3D image screen so that adjustments can be made.

In need of upgrading your wheel aligner for your workshop? See our full range of wheel aligners online now.

Contact us online today or call us on 01480 8-9-10-11 to discuss your requirements in more detail.Hofmann Megaplan's ATL & MoT equipment division continues to provide high quality equipment and service across the UK. While a bay is often considered as 1 large investment it is many smart pieces that make it up. This week we are looking at break testers.

Our range of durable brake testers are well known within the industry for their reliability and incredible precision. We have installed thousands of this product across the globe to ensure safe testing of cars, motorbikes and light commercial vehicles.

What's often more important when installing a brake tester is advice for the groundwork. Having someone who has done this many times and can help guide you on the depth needed to dig out, distances required all around and best position can save you money, time and effort.

Our latest install at Fusion Auto saw a fully comprehensive MoT equipment bay added, with the brake testers being easily accessible and with no visual obstructions. This install utilised every inch of space within the workshop where many may think an MoT Bay wouldn't fit.

What is a Roller Brake Tester?

A key component of MoT testing, due to the potential damage that can be caused by having faulty brakes, the brake tester is a must have. Whilst the vehicle is in a static position, the brake tester allows for dynamic assessment of the brakes and provides a detailed analysis of the condition.

How do Brake Testers work?

If you're new to MoT's you might have seen a break tester in action but not know exactly what it is doing.

The roller brake tester is designed to simulate a generic smooth road surface to ensure maximum tyre protection during the testing process.The vehicle is driven onto the brake tester with its wheels centrally located between the two large rollers. The rollers are then switched on once the vehicle's details have been entered and rotated at a consistent speed related to the vehicle type.

The vehicle's brakes are then applied by the operator. A transducer measures the braking force as the vehicle decelerates, creating an in-depth analysis for each wheel. During the process, fluctuation is also measured to determine balance of braking force between near and off side wheels. An output is displayed showing any difference.

Our brake testers are easy and efficient to use in most part due to the consideration we place on smart installs. The user is able to operate the machine whilst sitting inside the vehicle by a user-friendly control system.

Why are they so important?

As explained above, the brake tester is a vital piece of equipment for MoT testing. It could literally be the difference between life and death for anyone operating or sitting in the vehicle.

If faulty brakes are not flagged up because you've chosen to install an unreliable brake tester there could be devastating consequences.

Don't risk it. Visit Hofmann Megaplan ATL MOT now!

Luckily for you we are here to help! All our brake testers are DVSA approved. Contact us online now or call us today on 01480 891011 to book an appointment with our MoT Station specialists.

Back problems are no joke! Neither is failure to take care of yourself or your fitters. Lifting tyres takes its toll on the body. So why do it when there is a simple, safe and affordable solution?

Not only can it reduce the risk of injury but it can also boost the productivity of your garage.

Many fitters often overlook this forgotten about piece of garage equipment. However, wheel lifters could be one of the greatest investments you make in 2019! We've customers that have repeat purchased after seeing the difference purchasing one has made.

Stop slowing your service down. Here are the five reasons you need an electric wheel lifter!

1. Wheel Lifting Safety

An electric wheel lifter offers safety in a number of ways. Used effectively it reduces not only the risk of long term injury but also short term accidents. Wheels are securely locked into the tough grip arms. When working with wheels at height this means no risk of a falling tyre putting a fitter out of action.

Ensure all removals and movements are safe with minimal risk to your team, workshop and wheels!

2. Ease of Use at any Speed

What's incredible about this electric wheel lift is how feature rich it is, yet easy to use. The simple control panel offers quick access to lifting at one of three speeds. Using this simple bit of kit becomes second nature whilst eliminating a lifting job that no one need complete. What's more it takes up hardly any footprint in your garage (the reason many customers order one for each work bay). Increase the height you could lift a wheel manually with ease. Let a machine do the work!

3. Efficiency through Portability and Maneuverability

Our electric wheel lifter is battery powered making it completely portable and easy to transport around your workshop. Moving and fitting tyres becomes effortless and fast. At a fundamental level this wheel lifter makes you more productive and thus more profitable!

4. This Quality Device will change how you work without breaking the bank

We have not tried to reinvent the wheel. As with all products that wear the famous "H" logo, you receive the highest quality machine designed to last. This is a solution to issues many fitters just get on with and regret at some stage.

5. You can get a top spec Wheel Lifter at an incredible price!

This is a device we believe should be in every garage and tyre fitting shop. As such we are offering our highly rated WC300 Portable Electric Wheel Lifter for ONLY £995 +VAT!

Contact us online now or call us today on 01480 8-9-10-11 to order your electric wheel lifter now or for more info.

Although we haven't really had a severely cold winter this year, the weather is definitely becoming milder; which makes for happy riding if your one of the UK's 1.23 million registered motorbike owners (2017; Statista).

This makes for big business. It may be time to ask what it will take for you to capitalise on fitting wheels for motorcycles.

Motorbike Tyre Fitting: What do Hofmann Megaplan offer?

As with all our product ranges, Hofmann Megaplan only supply high quality premium garage equipment teamed with our now renowned impeccable service - our Motorcycle Equipment range is no acception!

Having been a leading supplier of garage equipment since 1931, our products and technology within them often sets the far future others to intimidate. It follows suit that we wouldn't offer a range of motorcycle tyre changing equipment and motorcycle lifting equipment with the famous 'H' logo on it, if we didn't feel it was up to scratch.

Our motorcycle tyre fitting equipment range consists of everything from lifting equipment like the MCL700 Motorcycle Lift through to motocycle wheel balancers including the Moto 200 Wheel Balancer. We also offer two motorcycle specific tyre changers:

While some class 4 tyre fitting machines will already be compatible with class 1 & 2 vehicles, we believe that there are many reasons investing in motorcycle specific equipment is the way to go in building the ultimate garage.

Why invest in Motorcycle specific equipment?

By purchasing specific garage equipment for your motorcycle tyre fitting services, you will be able to save time. This equipment is designed to do a specific job and while other changers will get the tyre on and off if you're looking to offer motorcycle fitting seamlessly this is a no brains investment.

What's more, when it comes to changing each tyre your equipment is already set up. This saves time and hassle for fitting all wheels as each machine is correctly set up with the right adaptors and its own purpose.

Of course, this can make your garage more profitable, your fitters lives easier and your business busy as you are able to fit in more jobs throughout the day. Your motorcycle tyre changing equipment can pay for itself quicker than you think and you seamlessly increase the number of specialised services you offer.

Visit our Hofmann Megaplan Motorcycle Equipment range now for more information!

Contact us online or call us today on 01480 891011 to discuss your garages requirements in more detail.

While Hofmann Megaplan's ATL & MoT equipment division continues to provide high quality equipment and service for a varying range of garage owners. However many are unaware of what equipment goes into an MOT, even though they know the profit it can bring them.

By providing a comprehensive range of products Hofmann Megaplan are able to fit out and upgrade bays with new MOT Equipment to suit more classes. This means better serving opportunities for your garage and not turning customers away. This includes:

What is our Most Popular MOT Bay Equipment?

Whilst no single piece is more important than another, their is always one piece of equipment that starts the search. Emission Testers are often this thing and are available for Class 1 & 2 MOT Testing, Class 4 MOT Testing & Class 7 MOT Testing. These vehicle gas analysers deliver the highest standard in petrol and diesel testing for your customer's peace of mind. Our MOT equipment range includes:

With technologically advanced components included as standard, UK MOT requirements are met with high quality performance products. Our emissions tester units also offer greater ease of use for your engineers and outstanding reliability, so you know that your equipment will not let you down!

What are you waiting for? Visit Hofmann Megaplan ATL MOT now!

Do you need more information or advice on what we can do to help your workshop? Contact us online now or call us today on 01480 891011 to book an appointment with our MoT Station specialists.There are a number of different pieces of equipment that make up an MOT Bay and understanding what is needed for classification can be a bit of a head spinner!

Here at Hofmann Megaplan, we pride ourselves on our MoT Bay knowledge and experience, having been a leading supplier of garage and MOT equipment since 1931.

Our specialist division for handling automotive testing equipment within the workshop, works to ensure you have the right equipment in your garage and to make sure your ATL MOT workshop operations run efficiently with little interruptions. They have put together the below quick beginners guide to understanding the different Class bay's when it comes to ATL/MOT.

Class 1 & 2 ATL MOT Bays

Many garages are unaware that their existing ATL MOT bay can be modified to cater for Class 1 & 2 vehicles, however having a specific Class 1 & 2 ATL MOT Bay can be highly beneficial to the efficiency of testing certain vehicles including:

- Motorbikes

- Scooters

- Mopeds

- Motorcycle Combinations (e.g. sidecar)

More often than not getting a Class 1 & 2 bay is a no brainer. By contacting our knowledgeable team we can provide specialist insight into achieving this.

Class 4 ATL MOT Bays

As your standard passenger car is the most popular form of transportation, it is of no surprise that Class 4 ATL MOT Bays are the go to when investing in MOT testing equipment. Due to the workload these bays see there is a need for them to be more robust and durable than ever.

Equipping your garage with the right Class 4 MOT bay can be a struggle though, as they can come in all shapes and sizes. By delivering our comprehensive analysis and design bespoke to your workshop, we can offer and advise on the best solution for your space and services. This peace of mind approach is imperative and ensures your bay is right and ready to start making you money ASAP!

Class 7 ATL MOT Bays

With heavy duty vehicles comes larger MOT testing equipment! Where the opportunity to get business from light commercial and heavy commercial machinery testing presents itself, you are going to need specialised Class 7 ATL MOT Bays and equipment to deal with the enormity of each task.

For dealing with the sheer weight and size of the vehicles, you will need a lot of space and very robust equipment. The need to plan well and get thing right first time is key, else a simple project could end up costing you more than needed.

If you need to draw on our expertise and advice for your MOT equipment, contact us online now or call us today on 01480 8-9-10-11 to speak with one of our MOT Station specialists.

You may have heard a lot of people talking about "old" and "new" gas in the world of vehicle Air Conditioning and wonder what it's all about? Well, firstly, there is no need to panic.

R134a, referred to as the old gas, will not be phased out. It will, however, be regulated and taxed heavily. Newer vehicles are being fitted with Air Conditioning Systems that operate using a new gas known as R1234yf.

Environmental Impact

The change is environmentally driven. More precisely, it is to do with the length of time refrigerants can remain in the upper atmosphere. R134a can take up to 10 years to breakdown into a non-greenhouse gas. About 25 years ago this was considered a vast improvement on R12 which had some 100 years plus life span before it broke down. R1234yf is another step forward in protecting our environment, taking between only three and four years to break down in the upper atmosphere.

You have Time

Relax! Now is the perfect time to train, tool up and offer vehicle air conditioning services using responsible air conditioning tools and systems. R1234yf has only recently been introduced, so there is plenty of time to understand the processes for dealing with the new gas. Currently, around 80% of vehicles will still be on R134a.

With the quick breakdown of R1234yf comes the need to purchase an up to date machine to recover and recycle the new refrigerant. You will also need to understand the new oil compatibility issues with R1234yf and what happens when refrigerants mix.

The performance of R1234yf is very similar to R134a. There will be no major changes to system components. There will however be to the H-block, hoses and the programming in the module that controls the HVAC system.

Your New Air Con Refrigerant

Current prices for the new refrigerant are high, at around double the cost of the old R134a. It's expected that this price will come down significantly in the next few years as production plants around the world ramp up output.

If you are looking to be ready and supply the R1234yf gases, why not look at the two most popular air conditioning units Hofmann Megaplan sell, the Megacool Fast 222YF and the Ermes YF.

Both machines are fully automatic with large 12KG tank capacities. They are suitable for all workshop applications. Please give us a call on 01213 516 329 if you require more information or contact us now on This email address is being protected from spambots. You need JavaScript enabled to view it..

I'm going to start this blog series by talking about one of our most common issues those working with wheel alignment equipment can face, and that's turn plates.

If not used correctly, turnplates can cause big problems when trying to achieve a straight steering wheel. Whats worse it can lead you to produce different results each time you attempt to align the same vehicle which quickly becomes infuriating.

Steer Clear of…

Some garages will try and use their MOT plates to save time and these can be ok to just turn the wheel and look for defects. The risk is that they get covered in dirt and that will get into the plate and cause a restriction. To complete an alignment accurately the plates need to be completely free moving.

Others might use their old style dish type turn plates. These most commonly come from an older laser system. They will turn but don't slide, meaning they build up tension and can give you wrong results.

Another common mistake made by alignment engineers is simply not using the pins provided. This is surprisingly common and can cause irreversible damage to your to your wheel alignment system.

Remember to…

We should always drive on the turn plates with the pins in. As soon as you are ready to remove a vehicle from your alignment station, put the pins in. Failing to do this can lead to damage when the car is reversed. The plate can tilt and bearings become loose, impacting the accuracy of your machine.

Some people simply fail to maintain their turn plates. Metal bearing plates will need regular lubrication for example with grease. Nylon bearings don't need any grease or oil but should be cleaned regularly depending on usage by removing the top plate and brushing out any dirt.

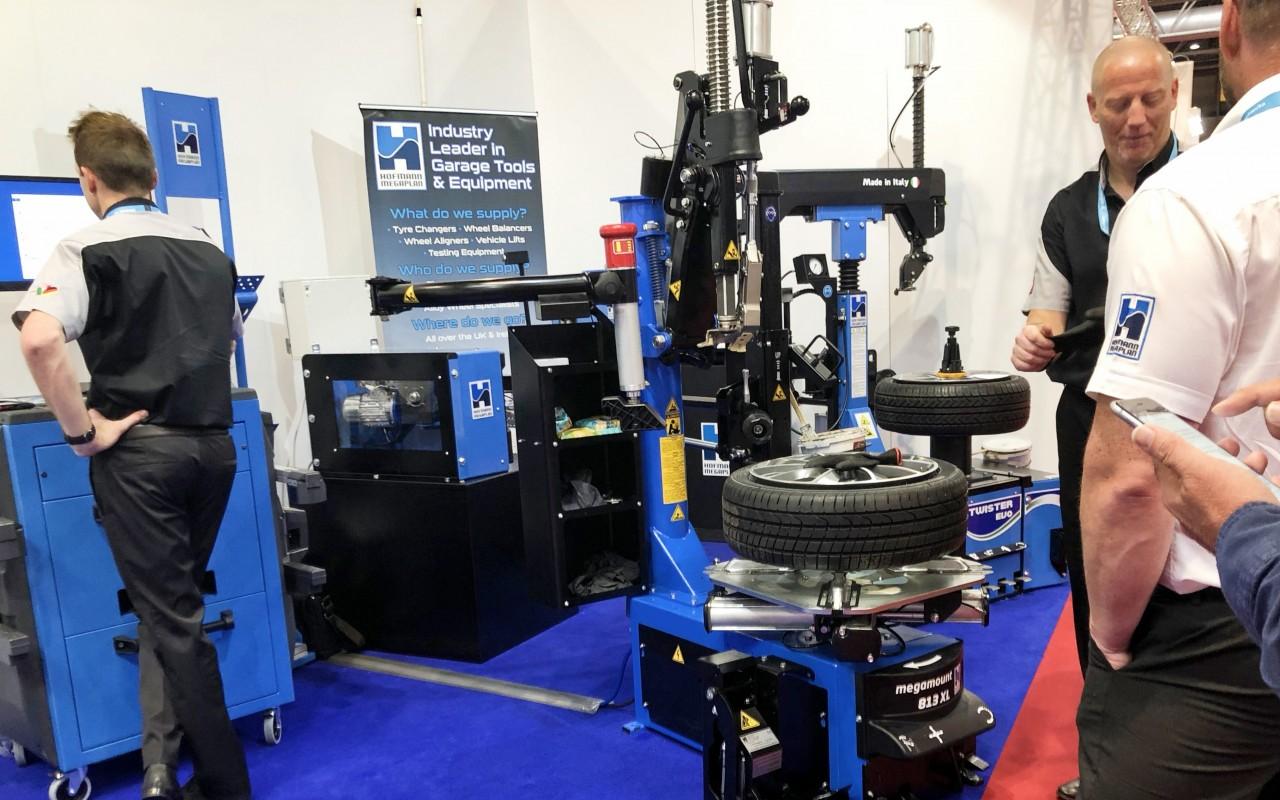

Hofmann Megaplan was pleased to see so many delegates from the automotive aftermarket and vehicle production sector at Automechanika 2018.

The 3-day event took place at the NEC, Birmingham and saw Hofmann Megaplan launch a number of new products including the OWB (One Weight Balance) technology for wheel balancing.

It was a record attendance at the show which also saw over 500 suppliers from over 26 countries set up stands in the 3 halls which the event took over.

New from Hofmann MegaplanThe Hofmann Megaplan stand was pushed for space with a wide variety of machines in operation for delegates to inspect. This included the brand new megamount 813xl which proved popular on its show debut. As the first of its kind in the market, this tyre changer is a fully automatic machine but without a traditional tilt back arm.

The Hofmann Megaplan team were on hand to explain to delegates how the innovative parallelogram design operates the mounting head with control and precision, removing all flex while fitting.

Wheel Alignment & Balancing

Alongside the OWB technology for balancing, a brand new wheel alignment system was also available for preview at the show. The Pulse 8 sits between the Ecoline 88 (ccd) and the Ssence 600 HD (3d) and is available to order now. Simply call 01480 8-9-10-11 to find out more now.

Automechanika 2018 proved a valuable opportunity for delegates to see the full range of wheel alignment machines Hofmann Megaplan offers side by side. If you missed out then a visit to the fully operational live demonstration showroom can also be booked by calling 01480 8-9-10-11.

The OWB (one weight balance) balancing software program that will be featuring on multiple machines, including the ms420, ms820, ms1200 and ms2000 was on show at Automechanika 2018. This was its first outing with many delegates impressed at the benefits the system can offer. For more on how OWB works speak to one of our experts today or arrange to visit us for a demo.

In Summary, Managing Director Mark Berryman said of the event "This was an extremely well run and slick operation. I take great pride in any opportunity Hofmann Megaplan has to showcase its incredible range of machines and Automechanika never fails to draw in the right crowd from all areas of the automotive and garage sectors. We look forward to returning next year."

Gallery

Other images from the Hofmann Megaplan team at Automechanika 2018:

The Hofmann Megaplan team celebrated in style this weekend at the companies annual Summer Party 2018.

This year's summer party offered the opportunity to congratulate all staff for what has been the most successful 6-months in the history of the company, making it a phenomenal first half to 2018.

This result is a testament to the knowledgeable and hard working team at Hofmann Megaplan. Their expertise has seen some huge orders across the board secured. This includes the range of tyre changers and wheel balancers that have become the bell-weather of garage equipment in the UK and Europe.

Ever growing in reputation in the same markets are the vehicle lifts offered by Hofmann megaplan. They are lighter, stronger and more robust than the competition. The wheel alignment machines range ensures equipment to suit every budget and requirement of even the most demanding garage or dealership. Add to this commercial equipment, nitrogen inflation and air conditioning machines and the range of garage equipment available and its success within the marketplace are truly great.

On every occasion the sales & scheduling teams have worked in harmony with our skilled engineers to ensure delivery, setup and training have been seamless, leaving customers satisfied every time.

The dedicated sales team, finance, parts, admin and management all had a great time celebrating what is turning into an amazing year for Hofmann Megaplan. Rest assured though, they will all be back ready to take your orders or answer your queries from Monday morning.

Give us a call on 01480 89 10 11 or request a callback.

Following a standard service and adjustment, there is nothing quite as frustrating as putting your alignment system away, only to find customers complaining that the steering wheel isn't straight when the vehicle is driving in a straight line.

This month we are going to look at a very common issue. Its one that regularly turns out to be the cause of misalignment yet is mostly nothing to do with your alignment system at all. However, it is all to do with how you use it. I'm going to tackle the all too common issues with alignment relating to the steering wheel straightness.

Following these steps and tips should help ensure the steering wheel and alignment match up every time:

- Firstly, ensure your machine is correctly calibrated

- Ensure your turn plates are in good condition

- Complete your vehicle pre-checks, I.E Tyre pressures, Tread wear, joint play etc.

- Check to see if you have clean lenses (CCD) or targets (3D)

- Ensure the clamps are fitted evenly around the rim (Ensure run out is done if using uncalibrated clamps I.E. 4 point)

- Always use 4 wheel alignment, not 2! (2 wheel alignment is only suitable for old vehicles where the rear wheels are hidden under arches.)

- You should not be sitting in the car when you put on the steering wheel clamp on. Instead, lean into the vehicle to avoid any change to the bump steer in the car.

- Remember: clamp your steering wheel straight as that is where it will be when driving straight ahead. (Many customers clamp the steering wheel near the end of a castor swing believing the computer is asking you to clamp when straightening the front wheels.)

- Continue with your alignment, bearing the below potential issues in mind.

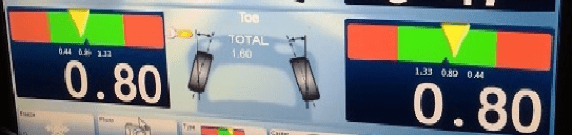

Post Alignment Check

At the end of the alignment process, and just before you start to remove the heads/clamps, on select systems you are able to click back to the front toe screen in the alignment program. If you remove the clamp and wiggle the steering wheel from side to side, the numbers on the screen should change accordingly. Now try and equal the toe numbers either side. Stand back – the steering wheel should be straight. If not, re-centre the wheel and re-adjust the toe.

Steering Wheel Alignment Issues to look out for:

- When undoing seized or tight lock nuts, the extra force used could move the steering wheel around. It is only the steering wheel clamp that holds the front wheels straight so be careful!

- I've found a lot of customers will heat up locked nuts or track rod ends to get them moving. As we know though, heat expands the metal and this can mean your system will give the incorrect readings. You can solve this by first getting the nut to move freely, then cooling it down with a cloth soaked in cold water. Now make the adjustment. You should be replacing the track rod ends as new MOT laws now forbid the heating of these components

Crabbing

Crabbing is a common term used by mechanics and customers alike, but it should really be referred to as a vehicles thrust line. This is the direction that the rear road wheels/ axle are pointing.

On more basic alignment machines, such as laser or even some computer systems, it is important to check the rear alignment as well. Failing to ensure the rear wheels are in-line with the front may cause the vehicle to "crab". This will mean you'll never get the steering wheel straight. The driver of this car would be turning their wheel to the left just to drive straight!

It is important to understand that the rear wheels are dictating the direction of the car and the front wheels are only compensating to keep the vehicle straight or steer. This is why it is important to find the thrust line and compensate for it when using lasers.Note: Most modern computers will compensate for this issue.

As a provider of wheel alignment services, chances are you know the advantages this service brings to your business but have you got the patter down on how to convey the benefits of alignment to your customers? Read on to find out the main arguments to put forward when someone is hesitant to sort their alignment.

Burning money on new rubber

New tyres can be costly. On average you can pay £110 per tyre so 4 tyres would be equivalent to a week's average wage. Depending on how bad the vehicle's alignment is, your customers could be wasting a tyre for every 4 you fit! They may try to blame the standard of tyre used or the quality of your job but it is important that they understand tyre will be subject to far more damage under the stresses of misalignment.

The car performs as intended

Mis-alignment means a car does not perform as it would have when driven out of the factory. Responsiveness in the steering will be impacted and the handling will suffer because the tyres will be struggling to do their job. Completing alignment checks and adjustments will help keep the vehicle on the road. Neglecting to do so is putting all the occupants at risk.

Improved Fuel efficiency means real savings

Many vehicle owners will often complain that their car seems to get through fuel quicker and quicker, but they do not realise how correct alignment can help a tank go further. Imagine having to push a car up a hill. Obviously, you're going to use much more energy than you would on a flat surface.

Effectively that's what your car is having to do when the alignment is out! The more you accelerate, the more fuel and power is needed to reach the same speed.

More than just wheels need replacing

It's not just the wheels that misalignment can wear away. As cars have gotten more advanced, the cost of components has also increased. Replacing wheel bearings with built-in speed sensors can cost a good few hundred pounds to buy and fit. Why do they need replacing? Because bearings get hot and wear prematurely due to miss alignment.

The same also applies to the bushes and joints on your car as they are having to work much harder simply to drag your tyres down the road. Expensive right?!

What can you do for your customers?

Just as the team at Hofmann always seek to advise our customers to ensure they get the most out of their tyre machines and garage equipment, you too can advise your customers and educate them as to why alignment is so important based on the above.

It is common practice to recommend your customer check their wheel alignment and have it adjusted as needed every 10,000 miles or at every service, whichever happens first.

Author | Warren Carr | Wheel Alignment Specialist

My name is Warren Carr and I'm from the team of alignment engineers at Hofmann Megaplan. I will be using this blog to regularly highlight some practical hints and tips which will help you, our garage professionals, achieve great results with your equipment, no matter the make of alignment machine.