Hofmann Megaplan Blog

Has anyone ever mentioned investing in a vehicle wheel lift? Maybe you've noticed as the day goes on your fitter's speed to carry out jobs decreases?

Vehicle wheels are heavy and you're probably lifting them more than you realise. Are the signs not clear enough yet?

You may be about to lose a valuable member of your team to serious back problems if you don't heed these signs of physical strain. Worse still, you could be out of action!

By investing in a safe and affordable wheel lift, you can look after the well-being of yourself, your team and boost the productivity of your garage at the same time.

Back, shoulder and neck injuries are very common within the industry and these problems are no joke! Manual handling injuries account for nearly half of all tyre-bay related incidents. (HSA)Taking the strain out of wheel lifting!

You could benefit immensely from investing in a reliable and sturdy wheel lift.

Check out our 5 reasons why you need a wheel lifter in our previous blog!

Raise your fitters' capabilities with the right wheel lift..

As you would come to expect from Hofmann Megaplan, we deliver high quality wheel lifting machines to reduce the health implications and improve the efficiency of your tyre bay or garage.

Ensuring you have the right wheel lift is crucial in guaranteeing the device is used regularly as a daily driver in your garage. Ease of use, portability and speed of operation are just some of the factors you'll be considering.

Unlike tyre changers and wheel balancers, wheel lifts are often forgotten about or the cheapest model on the market is purchased, but does not lead to operational efficiency. You spend more time annoyed at your rubbish wheel lift!Take a look at our reliable range of competitively priced Premium Wheel Lifts today:

Contact us online now or call us today on 01480 8-9-10-11 to order your electric wheel lifter now or for more info.

You may have heard a lot of people talking about "old" and "new" gas in the world of vehicle Air Conditioning and wonder what it's all about? Well, firstly, there is no need to panic.

R134a, referred to as the old gas, will not be phased out. It will, however, be regulated and taxed heavily. Newer vehicles are being fitted with Air Conditioning Systems that operate using a new gas known as R1234yf.

Environmental Impact

The change is environmentally driven. More precisely, it is to do with the length of time refrigerants can remain in the upper atmosphere. R134a can take up to 10 years to breakdown into a non-greenhouse gas. About 25 years ago this was considered a vast improvement on R12 which had some 100 years plus life span before it broke down. R1234yf is another step forward in protecting our environment, taking between only three and four years to break down in the upper atmosphere.

You have Time

Relax! Now is the perfect time to train, tool up and offer vehicle air conditioning services using responsible air conditioning tools and systems. R1234yf has only recently been introduced, so there is plenty of time to understand the processes for dealing with the new gas. Currently, around 80% of vehicles will still be on R134a.

With the quick breakdown of R1234yf comes the need to purchase an up to date machine to recover and recycle the new refrigerant. You will also need to understand the new oil compatibility issues with R1234yf and what happens when refrigerants mix.

The performance of R1234yf is very similar to R134a. There will be no major changes to system components. There will however be to the H-block, hoses and the programming in the module that controls the HVAC system.

Your New Air Con Refrigerant

Current prices for the new refrigerant are high, at around double the cost of the old R134a. It's expected that this price will come down significantly in the next few years as production plants around the world ramp up output.

If you are looking to be ready and supply the R1234yf gases, why not look at the two most popular air conditioning units Hofmann Megaplan sell, the Megacool Fast 222YF and the Ermes YF.

Both machines are fully automatic with large 12KG tank capacities. They are suitable for all workshop applications. Please give us a call on 01213 516 329 if you require more information or contact us now on This email address is being protected from spambots. You need JavaScript enabled to view it..

Over the duration of the lockdown months, the focus of the MOT sector has been set on the six-month extension announced by the DVSA - due to this, other areas of the MOT world (including MOT connected equipment) have taken a backseat.

Since the end of the lockdown, the DVSA’s “Beat the Rush” campaign has taken centre stage – often with mixed reviews.

The success of the rollout of Connected Roller Brake Testers back in October 2019 and Connected Decelerometers in February this year, is still unknown. However, a lot of garages have been experiencing some difficulties in working the connectivity, which has boiled down to a lack of knowledge by MOT equipment installers.

The biggest connected MOT issue...

All new roller brake testers and decelerometers installed into any garage must be connected to the MOT testing service.

It has been brought to the DVSA’s attention that issues with locating the “key” to connect equipment has been one of the biggest nuances for garage owners, after the install has been completed.

Official DVSA guidance for obtaining a key...

A DVSA spokesperson said: “When the engineer is on-site and ready to install your equipment you need to request a key and give it to them.

“The key will not work at another testing station and only works on one piece of equipment.”

To obtain a software code, users should sign into the MOT testing service and go to the ‘vehicle testing station’ page where they can ‘request a key’ under ‘change and connect equipment’.

Make sure you choose the MOT equipment experts

Ensuring you work with the experts is a must to getting it right first time.

Here at Hofmann Megaplan, our fully qualified engineers have been installing brand new MOT bays throughout the whole of lockdown. Many garage owners have seen the opportunity that has risen over the past couple of months and made sure their equipment is up to scratch to cope with any increase in demand.

Is it about time you did the same?

Check out our specialist MOT division online now or call our team on 01480 8-9-10-11.

Since the beginning of 2016, the regulations for headlamp testing has been altered. Due to this new change we have seen a dramatic increase in failure rates due to insufficient headlights.

It is more important than ever to be accurate and professional when testing this part of a vehicle and this responsibility extends to the equipment being used. That's why we've got some tips to see your headlight alignment tool working right for you.

Damage to your garage's reputation could be irreversible if you send an unfit vehicle out onto the road. That is why Hofmann Megaplan's MoT specialist division constantly tests its equipment as guidelines on MOT Tests are updated. We make sure your ATL MOT workshop operations run efficiently without interruptions and the correct knowledge and skills are passed onto you through our high quality product range.

MOT Matters: Headlamp Testers for the modern check

Quality of headlight testing equipment is not the only important factor. How a headlight beam tester is set up and being used is vital to a safe and compliant inspection. Failure to do so could result in inaccurate or unreliable results.

Our MoT experts are always on hand throughout our extensive installation service, to ensure you receive the best results.

To guarantee precise readings and performance you should always take into account the following factors:

- The position of the headlight beam tester - needs to be located on a level surface and have a permanent position in your workshop

- Adjustable rails - built into the ground so that they are level with the vehicle being tested

- Robust sliding column - decreasing the risk of deflection with a strong column. Also an electronic device has an advantage for more accurate measurements, over a mechanical and optically operated machine.

- Laser over Mirror - a more precise solution for the alignment of each headlamp

- Help from the experts - as part of any Hofmann Megaplan MoT Bay install we provide a full on site survey and advice as standard. Its the easiest way to get it right!

However, we can't take responsibility for any operational misuse.

Some Light Alignment Advice

There are a few other considerations that will mean successful headlight testing in your garage. Before the adjustments are taken, the wheels need to be straight in relation to the position of the car and all tyre pressures corrected when the vehicle is not loaded. In the case of vehicles with pneumatic suspensions, the engine should be operating during testing in order to maintain the correct ride height.

Quality Headlamp testing products - look for the HM!

- We continue to supply industry-leading headlamp beam testers.

- We make sure everything is working properly and runs smoothly with your garage's MoT services.

- We liaise with you during the planning, execution and the post-installation phases of the project.

- We always aim to deliver reliable headlamp testing equipment, that generates consistent results and dependable income.

What are you waiting for?

Check out our Headlight Testers today or visit our full range of Hofmann Megaplan MOT Equipment now!

Do you need more information or advice on what we can do to help your workshop? Contact us online now or call us today on 01480 8-9-10-11 to book an appointment with our MOT Station specialists.

MOT Bays are not just about the equipment. There is a host of requirements and regulations surrounding their install and legal running. The question is how much do you need to know and how much can the right partner help ease this pain?

Hofmann Megaplan have supplied and fitted high quality MOT bay packages with equipment and often more importantly, superb pre, during and after-sales service for many years.

We have built up an understanding of the common issues, pain points and best practices when putting together an MOT Bay.

In-depth knowledge and the required experience to tailor your new MOT service can be more valuable than the equipment itself.

From design concept to installation and your first MOT...

The first steps to supplying MOT services can sometimes be the biggest. The work involved in installing the right MOT equipment for your business starts way before ground is even broken.

A360-degree service is a must when installing your MOT Bay as it gives you full support from the early planning stages through to installation.

Offering total project management and advising on MOT equipment to suit your services, the likes of Hofmann Megaplanare able to provide and source the right outfit for your new MOT testing bay based on your space and our specialist industry knowledge.

Expert after-sales service...

MOT test lanes remain reliable and accurate if they are looked after. Simple.

This is the most crucial stage of any MOT installation service; the care and training supplied to help you increase the efficiency and longevity of your new bay. Passing on knowledge to help you succeed in the future should be a part of the package you receive.

Calibrations. Certifications. Servicing. Any reputable supplier should be able to offer this. Hofmann Megaplan are proud to fully manage MOT projects and offer all the support required once you are up and running.

Hofmann Megaplan go the extra mile...

Our team always aim for an exceptional service.

The above & beyond standard we set ourselves means you have everything you need to succeed in your MOT service.

The most comprehensive MOT bay install service in the UK just got better!

But there's less than two weeks left to claim your 1st year calibrations for FREE!

Let us take the reins!

Are you puzzled by the complexities of ATL MOT? Are you currently searching for the perfect MOT station for sale?

Contact us online today or call our dedicated team on 01480 8-9-10-11 for a friendly chat to discuss your new or upgrading MOT services.

ADAS Calibration Equipment is still a relatively new phenomenon. Investment in it is a big decision that can for many, be one massive headache.

Speaking to someone who understands ADAS services & the full scope of systems on offer can be essential; especially when it comes to such a large investment which will enable you to complete the ADAS calibrations your customers now require.

You’ve probably been thinking something like “Ok, ADAS is a thing. Do any of my customer even need these calibrations? Oh, I should be completing it after a variety of jobs? It can be an extra source of income? My competitors are offering it now & pinching customers promoting it? There are digital & analogue systems? It costs what? Can I afford not to have it? What system do I need?”

Sounds familiar?

Is there a best ADAS Calibration System?

In short, no.

ADAS is one of the biggest technological advancement in automotive services in the last decade. That means you need a machine that of keeping up with changes to come as cars continue to develop.

For many garage owners, the hefty investment in ADAS calibration equipment can be tough to justify. There are two main systems though catering to different technology levels.

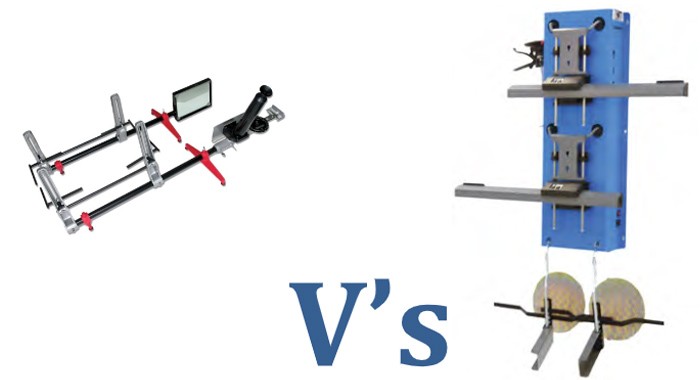

The ADAS Analogue system utilises a more traditional set up of printed boards & a simple manual measurement system, helping to keep initial outlay lower whilst enabling you the ability to complete ADAS calibrations. It is more labour intensive to set up though & new boards need to be purchased to keep it up to date.

Alternatively, a larger investment is needed in the digital solution, which uses a 65” monitor to display boards intelligently to suit the position of the car in front of it. Add to this laser measurement & this system is operable by a single technician saving labour & receives updates over the air for new updates.

As with any piece of garage equipment, knowing which system is best for your garage can only be determined by speaking to the experts! We’d advise booking a visit to the Hofmann Megaplan Centre of Excellence to try both systems out for yourself before making an investment.

CALL NOW TO BOOK

What are you waiting for?

Call our team today on 01480 8-9-10-11 and get the wheels in motion for the purchase of your first ADAS calibration system. Digital or analogue, that should be your only question!

Every car over three years old needs an MOT to be road legal. Light commercial vehicles and motorcycles need them too, so demand for testing is always high, year-round, no matter which type of vehicle your workshop specialises in. If you don’t currently offer MOT testing in-house and would like to, your first question may well be the one posed in the title of this article: what equipment do I need? Let’s take a closer look at each piece of equipment used in an MOT test.

MOT testing equipment

Typically, garages looking to branch out into MOT testing will choose a complete MOT bay installation, which includes all of the necessary components to carry out accurate, compliant testing. It’s much easier to take this route than it is to buy equipment individually.

Our Class 4 MOT bays include the following pieces of equipment:

- Four-post lift: A robust, easy-to-use lift that’s perfect for inspecting vehicles. A four-post lift is ideally suited to MOT testing, as it takes just seconds to get the vehicle up in the air but still provides enough access to check for play in bushes, exhaust leaks, corrosion and other potential failure points.

- Radius (or turn) plates: Not an essential item legally, but a must-have for busy MOT garages nonetheless. Radius plates allow a vehicle’s wheels to be turned without using the steering wheel, allowing a tester to quickly and easily check the operation of the steering from outside and underneath. Much easier than asking a colleague to hop in and turn the steering wheel!

- Play detector: A straightforward device used to check for play in suspension bushes - a common failure or advisory point on an MOT test.

- Jacking beam: Mounted to the four-post lift, a jacking beam makes it easy to lift the vehicle off the ground while it’s still in the air - perfect for checking play in wheel bearings, for example.

- Headlight beam tester: A machine that efficiently assesses the aim of a vehicle’s headlight beam. Using it, a tester can quickly determine whether or not the beam needs adjusting, before making the necessary alterations to pass the vehicle.

- Brake tester: A vital component of the MOT test. Brakes are perhaps the single most important safety component on a vehicle, and this machine will make sure they’re in good working order. Not only will it assess the overall stopping power of the vehicle, it’ll let the tester know if there are potentially dangerous imbalances across an axle.

- Smoke and gas analyser: Used to analyse the emissions from a vehicle’s tailpipe. A variety of parameters are recorded and compared against maximum legal requirements, giving you a clear pass or fail result.

Get your quote today

Ready to learn more and begin planning your MOT bay installation? Learn more about the services we have to offer today, or contact us to get your own tailored installation quote.

Back problems are no joke! Neither is failure to take care of yourself or your fitters. Lifting tyres takes its toll on the body. So why do it when there is a simple, safe and affordable solution?

Not only can it reduce the risk of injury but it can also boost the productivity of your garage.

Many fitters often overlook this forgotten about piece of garage equipment. However, wheel lifters could be one of the greatest investments you make in 2019! We've customers that have repeat purchased after seeing the difference purchasing one has made.

Stop slowing your service down. Here are the five reasons you need an electric wheel lifter!

1. Wheel Lifting Safety

An electric wheel lifter offers safety in a number of ways. Used effectively it reduces not only the risk of long term injury but also short term accidents. Wheels are securely locked into the tough grip arms. When working with wheels at height this means no risk of a falling tyre putting a fitter out of action.

Ensure all removals and movements are safe with minimal risk to your team, workshop and wheels!

2. Ease of Use at any Speed

What's incredible about this electric wheel lift is how feature rich it is, yet easy to use. The simple control panel offers quick access to lifting at one of three speeds. Using this simple bit of kit becomes second nature whilst eliminating a lifting job that no one need complete. What's more it takes up hardly any footprint in your garage (the reason many customers order one for each work bay). Increase the height you could lift a wheel manually with ease. Let a machine do the work!

3. Efficiency through Portability and Maneuverability

Our electric wheel lifter is battery powered making it completely portable and easy to transport around your workshop. Moving and fitting tyres becomes effortless and fast. At a fundamental level this wheel lifter makes you more productive and thus more profitable!

4. This Quality Device will change how you work without breaking the bank

We have not tried to reinvent the wheel. As with all products that wear the famous "H" logo, you receive the highest quality machine designed to last. This is a solution to issues many fitters just get on with and regret at some stage.

5. You can get a top spec Wheel Lifter at an incredible price!

This is a device we believe should be in every garage and tyre fitting shop. As such we are offering our highly rated WC300 Portable Electric Wheel Lifter for ONLY £995 +VAT!

Contact us online now or call us today on 01480 8-9-10-11 to order your electric wheel lifter now or for more info.

I'm going to start this blog series by talking about one of our most common issues those working with wheel alignment equipment can face, and that's turn plates.

If not used correctly, turnplates can cause big problems when trying to achieve a straight steering wheel. Whats worse it can lead you to produce different results each time you attempt to align the same vehicle which quickly becomes infuriating.

Steer Clear of…

Some garages will try and use their MOT plates to save time and these can be ok to just turn the wheel and look for defects. The risk is that they get covered in dirt and that will get into the plate and cause a restriction. To complete an alignment accurately the plates need to be completely free moving.

Others might use their old style dish type turn plates. These most commonly come from an older laser system. They will turn but don't slide, meaning they build up tension and can give you wrong results.

Another common mistake made by alignment engineers is simply not using the pins provided. This is surprisingly common and can cause irreversible damage to your to your wheel alignment system.

Remember to…

We should always drive on the turn plates with the pins in. As soon as you are ready to remove a vehicle from your alignment station, put the pins in. Failing to do this can lead to damage when the car is reversed. The plate can tilt and bearings become loose, impacting the accuracy of your machine.

Some people simply fail to maintain their turn plates. Metal bearing plates will need regular lubrication for example with grease. Nylon bearings don't need any grease or oil but should be cleaned regularly depending on usage by removing the top plate and brushing out any dirt.

Hofmann Megaplan's ATL & MoT equipment division continues to provide high quality equipment and service across the UK. While a bay is often considered as 1 large investment it is many smart pieces that make it up. This week we are looking at break testers.

Our range of durable brake testers are well known within the industry for their reliability and incredible precision. We have installed thousands of this product across the globe to ensure safe testing of cars, motorbikes and light commercial vehicles.

What's often more important when installing a brake tester is advice for the groundwork. Having someone who has done this many times and can help guide you on the depth needed to dig out, distances required all around and best position can save you money, time and effort.

Our latest install at Fusion Auto saw a fully comprehensive MoT equipment bay added, with the brake testers being easily accessible and with no visual obstructions. This install utilised every inch of space within the workshop where many may think an MoT Bay wouldn't fit.

What is a Roller Brake Tester?

A key component of MoT testing, due to the potential damage that can be caused by having faulty brakes, the brake tester is a must have. Whilst the vehicle is in a static position, the brake tester allows for dynamic assessment of the brakes and provides a detailed analysis of the condition.

How do Brake Testers work?

If you're new to MoT's you might have seen a break tester in action but not know exactly what it is doing.

The roller brake tester is designed to simulate a generic smooth road surface to ensure maximum tyre protection during the testing process.The vehicle is driven onto the brake tester with its wheels centrally located between the two large rollers. The rollers are then switched on once the vehicle's details have been entered and rotated at a consistent speed related to the vehicle type.

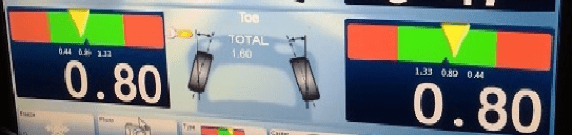

The vehicle's brakes are then applied by the operator. A transducer measures the braking force as the vehicle decelerates, creating an in-depth analysis for each wheel. During the process, fluctuation is also measured to determine balance of braking force between near and off side wheels. An output is displayed showing any difference.

Our brake testers are easy and efficient to use in most part due to the consideration we place on smart installs. The user is able to operate the machine whilst sitting inside the vehicle by a user-friendly control system.

Why are they so important?

As explained above, the brake tester is a vital piece of equipment for MoT testing. It could literally be the difference between life and death for anyone operating or sitting in the vehicle.

If faulty brakes are not flagged up because you've chosen to install an unreliable brake tester there could be devastating consequences.

Don't risk it. Visit Hofmann Megaplan ATL MOT now!

Luckily for you we are here to help! All our brake testers are DVSA approved. Contact us online now or call us today on 01480 891011 to book an appointment with our MoT Station specialists.

As all garages will know by now, tyre changing, wheel balancing and wheel alignment all go hand in hand when it comes to your customer's tyres. The simple fact is all these services provide crucial steps to ensure longevity, safety and efficient tyre/vehicle performance.

The only issue is, many of your customers are not aware of this.

Educating your customers beyond a price-driven view of tyre fitting services can be difficult, especially when it can be misconceived as upselling your own services.

Some garages don't see the need for a vehicle alignment machine as their customers don't want it. Many owners, therefore, opt to purchase a tyre changer and a wheel balancer as a package, then see wheel alignment as an added extra if the demand is there. These garages often end up turning business away as customers are smart enough to ask about alignment.

So, where do you stand when it comes to providing wheel alignment to your customers?

Why is wheel alignment so important?

It is always strongly advised for your customers to have their wheels aligned when new tyres are fitted; but again, customers mistake tracking for proper wheel alignment, and even mix up wheel balancing with wheel alignment.

A wheel aligner simply looks at the position of the wheels in relation to each other and the road surface, so that any corrections can be made.

Missing out this crucial step can cause minor and major issues to the tyres and driving performance, in both the short term and long term.

Check out our previous blog to discover the full importance of wheel alignment services!

The need for wheel alignment in your garage is clear. Especially if you are dealing with numerous tyre fitting jobs per day.

Not only will your customers reap the benefits of that extra service, but you can see many advantages within the garage - not least an obvious increase in revenue!

The right wheel aligner for your garage!

Think about the amount of tyre fitting jobs you complete each week or even each day...

Every single tyre fitting job you complete should have an alignment check when the tyres are installed onto the car!

A simple question then - are you completing those checks? Are you even offering them?

Ensuring you purchase the right wheel aligner for your garage services needs a considered approach. By making sure you have the essential footprint to install the wheel aligner, guaranteeing the durability to cope with your garage services, and the all-important budget to consider, you can be well on your way to conquering the perfect set of tyre fitting services.

Check out our entire range of wheel alignment machines online today!

Don't feel abandoned when considering your wheel alignment options!

Check out our range of Wheel Aligners and ADAS Calibration Equipment today.

Contact us online now or call us today on 01480 8-9-10-11 to speak to one of our dedicated team for more information.

Following a standard service and adjustment, there is nothing quite as frustrating as putting your alignment system away, only to find customers complaining that the steering wheel isn't straight when the vehicle is driving in a straight line.

This month we are going to look at a very common issue. Its one that regularly turns out to be the cause of misalignment yet is mostly nothing to do with your alignment system at all. However, it is all to do with how you use it. I'm going to tackle the all too common issues with alignment relating to the steering wheel straightness.

Following these steps and tips should help ensure the steering wheel and alignment match up every time:

- Firstly, ensure your machine is correctly calibrated

- Ensure your turn plates are in good condition

- Complete your vehicle pre-checks, I.E Tyre pressures, Tread wear, joint play etc.

- Check to see if you have clean lenses (CCD) or targets (3D)

- Ensure the clamps are fitted evenly around the rim (Ensure run out is done if using uncalibrated clamps I.E. 4 point)

- Always use 4 wheel alignment, not 2! (2 wheel alignment is only suitable for old vehicles where the rear wheels are hidden under arches.)

- You should not be sitting in the car when you put on the steering wheel clamp on. Instead, lean into the vehicle to avoid any change to the bump steer in the car.

- Remember: clamp your steering wheel straight as that is where it will be when driving straight ahead. (Many customers clamp the steering wheel near the end of a castor swing believing the computer is asking you to clamp when straightening the front wheels.)

- Continue with your alignment, bearing the below potential issues in mind.

Post Alignment Check

At the end of the alignment process, and just before you start to remove the heads/clamps, on select systems you are able to click back to the front toe screen in the alignment program. If you remove the clamp and wiggle the steering wheel from side to side, the numbers on the screen should change accordingly. Now try and equal the toe numbers either side. Stand back – the steering wheel should be straight. If not, re-centre the wheel and re-adjust the toe.

Steering Wheel Alignment Issues to look out for:

- When undoing seized or tight lock nuts, the extra force used could move the steering wheel around. It is only the steering wheel clamp that holds the front wheels straight so be careful!

- I've found a lot of customers will heat up locked nuts or track rod ends to get them moving. As we know though, heat expands the metal and this can mean your system will give the incorrect readings. You can solve this by first getting the nut to move freely, then cooling it down with a cloth soaked in cold water. Now make the adjustment. You should be replacing the track rod ends as new MOT laws now forbid the heating of these components

Crabbing

Crabbing is a common term used by mechanics and customers alike, but it should really be referred to as a vehicles thrust line. This is the direction that the rear road wheels/ axle are pointing.

On more basic alignment machines, such as laser or even some computer systems, it is important to check the rear alignment as well. Failing to ensure the rear wheels are in-line with the front may cause the vehicle to "crab". This will mean you'll never get the steering wheel straight. The driver of this car would be turning their wheel to the left just to drive straight!

It is important to understand that the rear wheels are dictating the direction of the car and the front wheels are only compensating to keep the vehicle straight or steer. This is why it is important to find the thrust line and compensate for it when using lasers.Note: Most modern computers will compensate for this issue.

Looking to enhance your garage revenue with wheel alignment? Maybe your customers are becoming wiser to alignment and searching for a more comprehensive service? Offering 4 wheel laser alignment could be the answer.

Every garage is looking for new ways to strengthen their services - especially within alignment. Having proved to be one of the most lucrative sources of revenue throughout the automotive equipment industry, wheel alignment is continuing to evolve.

4 Wheel Laser wheel alignments may be the next step in conquering your closest rivals. Step one: understanding it!

4 Wheel Laser vs Optical Gauges

From the uninitiated, we often get asked the difference in these terms and how they are related if not the same thing.

Put simply, 4 wheel laser alignment measures on all four wheels ensuring the car is no longer crabbing, a phrase to remember is the "rear wheels steer the vehicle". Also when you consider 70% of manufacturers now have rear tracking as well as the front, there is extra revenue to be made, but the most important aspect is you will have a straight steering wheel which means no more driving down the road making adjustments on the side of the road.The generic process of Optical gauges will check the track of the front and rear wheels only, but will not straighten the steering wheel or stop the car crabbing which is highly important on todays modern cars because of the highly complex electronics such as ADAS.

Naturally 4 wheel laser alignment is a more lucrative service to offer when compared to Optical gauges, and the results from 4 wheel laser alignment means better performance from your customer's vehicle.

4 Wheel Laser Wheel Alignment Explained

You shouldn't be overwhelmed by this technology as it is becoming common place in garages across the UK.

Car wheels are not just set up to just point forwards. To ensure the car drives smoothly and functions properly, the wheels are set up to point at specific angles. These angles can be tiny but failing to set them up can ruin the driver's experience.

Laser alignment makes this process simple, using light beams to project any misalignments onto the 3D image screen so that adjustments can be made.

In need of upgrading your wheel aligner for your workshop? See our full range of wheel aligners online now.

Contact us online today or call us on 01480 8-9-10-11 to discuss your requirements in more detail.The writing has been on the wall for diesel cars for a few years now - since the infamous dieselgate scandal swept the industry - but sales on the second-hand market have remained strong. Until now, that is. For the first time, online used car remarketing platform Autorola has reported a decline in demand for second-hand diesel vehicles. Over the course of 2022, diesel sales fell by a not-insignificant 15.1%. Gone are the days of diesel domination: last year, just one in four vehicles sold through the platform was so-powered.

Jumping ship

So, what are motorists buying instead? According to Autorola’s stats, petrol power is now by far and away Britain’s preference. Last year, sales increased by 28.9%, representing 64.9% of total sales. The biggest winners of 2022 though, perhaps unsurprisingly, were hybrid and electric cars. Sales of these lower-emission models shot up by 52.6% in the last 12 months, making up 8.9% of total sales. Although this figure sounds small, we can expect it to increase significantly in the coming years, in-line with new vehicle sales.

Offering further insight, Autorola UK’s group sales director, Jon Mitchell, added: “We are witnessing a shift in the type of stock we are selling, with diesels proving less popular and petrols and hybrids increasing in popularity.” Interestingly, he noted that hybrids are currently performing better than full EVs on the second-hand market: “Used EV demand and prices are falling during the current cost-of-living crisis, which is helping boost both petrol and hybrid sales,” he said.

Do you run a garage?

If you run a workshop of your own and are looking to invest in the very best garage service equipment the industry has to offer, look no further than Hofmann Megaplan. View our full range of machinery online today.